The development and commercialization of austempered ductile iron (ADI) has provided the design engineer with a new group of cast ferrous materials which offer the exceptional combination of mechanical properties equivalent to cast and forged steels and production costs similar to those of conventional Ductile Iron. In addition to this attractive performance: cost ratio, AUSTEMPERED DUCTILE IRON (ADI) also provides the designer with a wide range of properties, all produced by varying the heat treatment of the same castings, ranging from 10-15% elongation with 125 ksi (870 MPa) tensile strength, to 250 ksi (1750 MPa) tensile strength with 1-3% elongation. Although initially hindered by lack of information on properties and successful applications, Austempered Ductile Iron (ADI) has become an established alternative in many applications that were previously the exclusive domain of steel castings, forgings, weldments, powdered metals and aluminum forgings and castings.

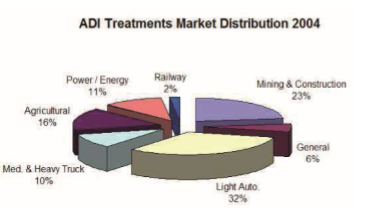

The Austempered Ductile Iron (ADI) market represents nearly all segments of manufacturing. Bellow fig shows the approximate break down of the Austempered Ductile Iron (ADI) market.

Heavy Truck and Bus Components

Economic growth drives the need to haul heavier loads over longer distances, resulting in more time between vehicle maintenance and some difficult engineering challenges. The Heavy Truck industry recognised the potential benefits of Austempering solutions many years ago. Manufacturers took advantage of the versatility of Austempered Ductile Iron (ADI) to introduce innovative light weight, high performance parts. Diesel Engine Timing Gears, Hypoid Ring and Pinion Gears, Jack Stand Gears, Wheel Hubs, Suspension Brackets these are some components which are manufactured by using austempering ductile iron.

Railway

The Railway industry is constantly looking to improve its products and the safety and efficiency of rail transport. The railroad industry uses ADI for suspension housings, top caps and friction wedges, track plates, repair vehicle wheels, nipper hooks, and car wheels.

Construction Equipment

Heavy duty and hard working, construction equipment can benefit greatly from the use of tough, wear resistant Austempered Irons and Steels. Whether for ground engaging components such as bucket teeth or engine and powertrain parts, Austempered Ductile Iron (ADI) and other Austempered materials can improve the performance of your equipment.

Light Vehicle

The automotive industry is constantly looking to increase performance, and reduce the cost and weight of the vehicles they produce. Austempered materials have a proven track record of providing strength and dependability for safety components, suspension systems, and drivetrain applications.

Miscellaneous Industrial Miscellaneous industrial applications include brackets, lever arms, knuckles, shafts, cams, sway bars, sleeves, clevises, conveyor components, jack components, bushings, rollers, molding line components, fixtures, gears, sprockets, deck plates, and all sorts of power transmission and structural components.

Agricultural Farming and agricultural applications for Austempered Ductile Iron (ADI) include plow points, till points, trash cutters, seed boots, ammonia knives, gears, sprockets, knotter gears, ripper points, tractor wheel hubs, rasp bars, disk parts, bell cranks, lifting arms, and a great variety of parts for planters, plows, sprayers and harvesters.

Sporting Goods

Even the sports goods industry has adopted Austempered Ductile Iron (ADI) for its high strength to weight and superior wear resistance. Bobsleigh runners, Sword blades, Gun components are manufacturing by using austempered ductile iron.

Defense The defense industry has been relatively slow to adopt Austempered Ductile Iron (ADI), however some of the applications include track links, armor, ordnance and various hardware for trucks and armored vehicles.

Gears/Shafts/Powertrain

For high performance gear and power train manufacturers, Austempered materials offer greater wear resistance, reduced noise, improved bending and contact fatigue, as well as increased strength and durability. Diesel Engine Timing Gears, Hypoid Ring and Pinion Gears, Off-Highway Drive Axles, Ring Gears, Gear Housings, Sprockets, CV Joints, Differential Housings, Wheel Hubs etc are prepared by using austempered ductile iron.